3D Printing Design Tips & TricksThere are several design advantages to keep in mind for making your 3D printed custom parts more cost-effective. from Xometry

1. Reduce Z-height - Shorter parts yield quicker builds, which saves cost. Splitting complex parts can also be more economical than increasing height.

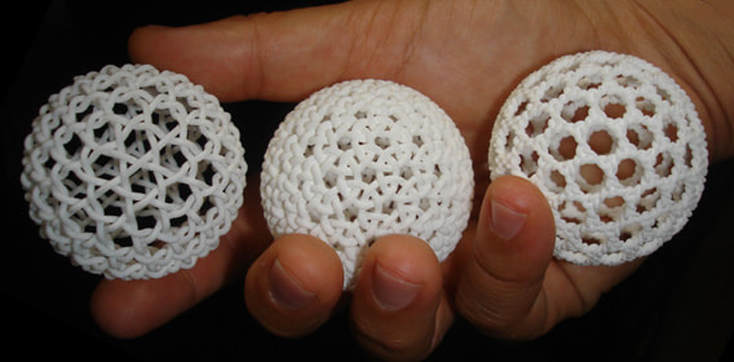

2. Reduce part volume - Use less material by creating pockets or changing the infill of the design (Xometry offers Ultralight, Light, and Solid infill options for FDM). For SLS, you may want to consider hollowing out large volumes.

3. Choose the right process - Keep design considerations such as strength, tolerance, and physical appearance of your part in mind. In many cases you can save a lot when there is flexibility on material and surface finish.

4. Test a feature before building the full part - When experimenting with multiple iterations, test smaller sections before the entire piece.

1. Reduce Z-height - Shorter parts yield quicker builds, which saves cost. Splitting complex parts can also be more economical than increasing height.

2. Reduce part volume - Use less material by creating pockets or changing the infill of the design (Xometry offers Ultralight, Light, and Solid infill options for FDM). For SLS, you may want to consider hollowing out large volumes.

3. Choose the right process - Keep design considerations such as strength, tolerance, and physical appearance of your part in mind. In many cases you can save a lot when there is flexibility on material and surface finish.

4. Test a feature before building the full part - When experimenting with multiple iterations, test smaller sections before the entire piece.